Meet Our Amazing Team

Our staff is extremely qualifed to help your business grow

Let us Take care of your Projects

MSW Incineration System

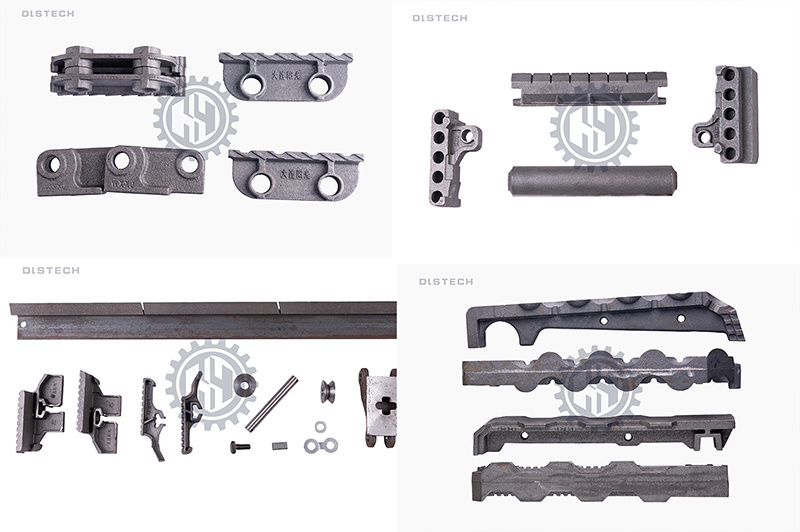

Boiler Auxiliaries equipment

Reciprocating Step grate for MSW

What we do best?

HUIYING MACHINERY

Goals give us focus!

Devote all our efforts to Support Customers.

We respect, support and trust each other, Always Strengthen Our TEAM Relationships. Provide the highest level of professionalism in planing and delivering services to our clients.

HUIYING MACHINERY

Technical solutions has experienced staff and reputable projects.

Technical solution: to be pre-engineered technical solutions to provide fast response, cost saving, low maintenance and longer operating life of all project conditions and requirements.

What Our Clients Say

Some Kind Words From Our Respected Clients

Victor from Chile

I often buy grate casting accessories. The quality of the reciprocating grate bars, rollers is very good, the material is certified, and Dalian Huiying is a more trusted supplier. Thanks to Dalian Huiying for supplying the grate stoker, which has been a great help to the production of my factory.

Kanta From Indonesia

We have been following this factory for a long time and heard that they have 27 years of production experience. I decisively chose them for this purchase of boiler grates. I really didn't disappoint!

Excellent quality: The grate has solid workmanship, thick and wear-resistant materials, and the stability and heat dissipation effect during operation far exceed expectations, fully meeting industrial standards;

After sales professional: There is a dedicated person providing remote guidance during installation and debugging, with a particularly fast response speed. The after-sales team patiently answers technical questions and proactively reminds maintenance details.

Domingo from Philippines

I have been repurchasing products from this factory for nearly 10 years, buying 10t/h, 12t/h, and 15t/h. This time, I specifically purchased matching accessories for the boiler grate, and the experience still exceeded expectations!

The material and process of the accessories are completely consistent with the previously purchased grate, with a delicate and burr free surface treatment. After installation, they run seamlessly without any looseness or abnormal noise issues;

The old grate has been used for seven or eight years, and the new accessories can be directly installed.

This old factory's consistent attention to detail and customer service make it worth long-term cooperation!

NEWS

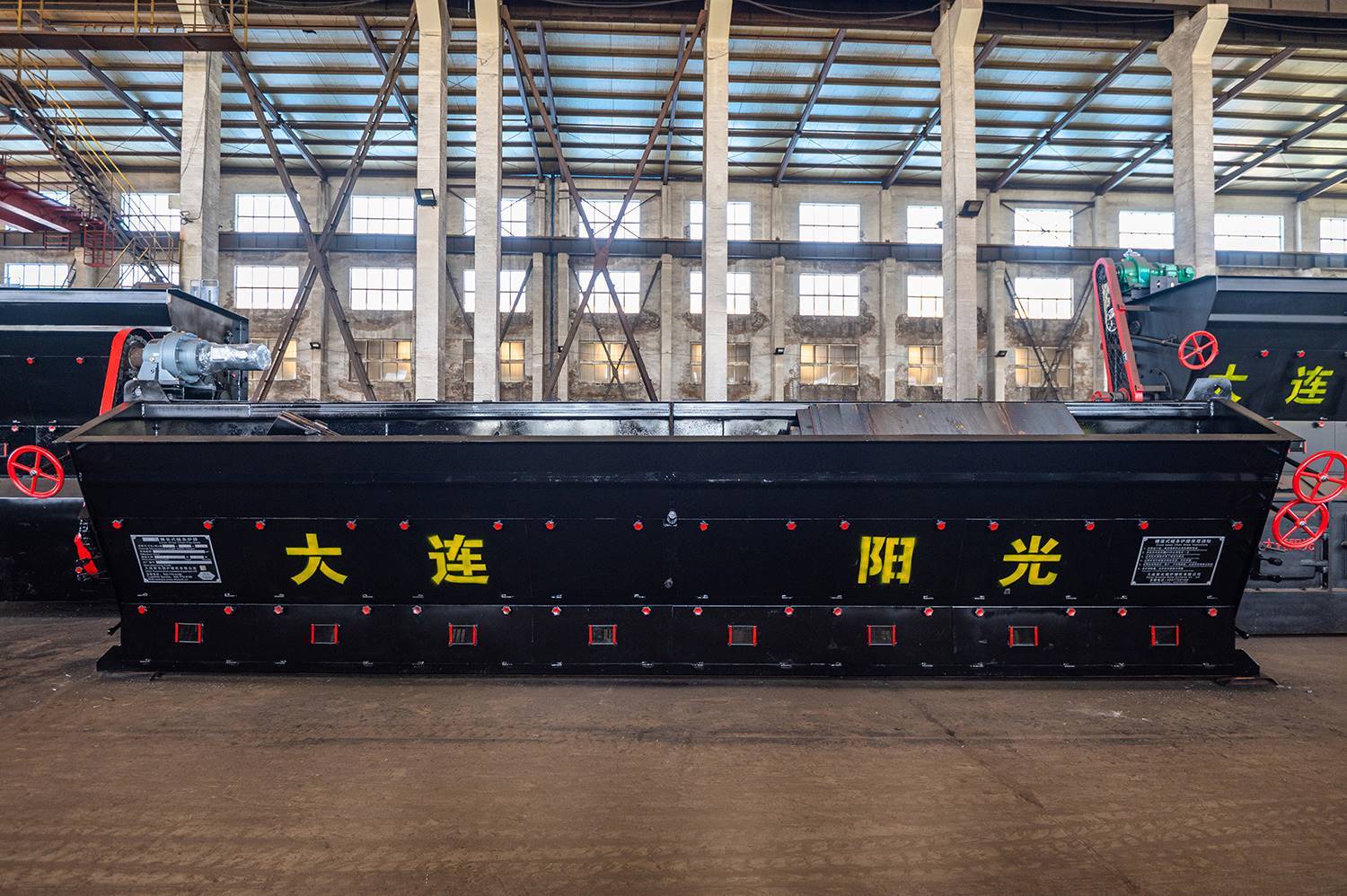

Two 4-ton chain-grate furnaces have been shipped to Wuxi.

The grate surface of the chain-type grate is actually the chain belt itself. The chain belt is driven by sprockets, causing the grate bars to move slowly forward. The grate bars are typically made of cast iron; after assembly, necessary ventilation gaps are maintained between the individual bars. Moreover, a compartmentalized ventilation chamber with adjustable air flow is often installed beneath the grate, allowing air to enter the fuel layer through these gaps and facilitate combustion.

One 15-ton large-grate furnace has been shipped to Henan.

Dalian Huiying Machinery Co., Ltd. was established in 2006 and currently has fixed assets exceeding 500 million yuan. Founded in 1998, the company operates under the principle of “doing our utmost,” practicing green and low-carbon production. Located in the Yaojia Industrial Zone, Nanguanling Town, Ganjingzi District, Dalian City, it is one of China’s largest manufacturers of auxiliary boiler equipment.

25-ton large-block horizontal beam grate furnace shipped.

The conversion from large-grate furnaces (large-scale plate or large-scale chain grates) to beam-type grates primarily aims to address the structural defects of large-grate furnaces, enhance operational reliability, improve combustion efficiency and environmental performance, and make them suitable for larger capacities and more complex fuels.

Wafangdian Dalian Huiying Machinery Recruitment Information

Welder—10 positions, male applicants only. No educational requirements; age 20–55 years old. Monthly salary around 8,000 yuan. The job involves welding the exterior of furnace grates. Applicants must be proficient in oxy-acetylene welding and solid-wire welding, with no carbon inclusion allowed. Most work will involve welding thin plates. Applicants who can read blueprints and have practical experience in this industry are preferred.

Dalian Huiying Machinery Factory ships a 15-ton chain-grate furnace.

Huiying Machinery Factory ships a 15-ton chain-grate furnace.

Dalian Huiying Machinery has shipped two 2-ton chain-grate furnaces to Guangdong.

Dalian Huiying Machinery Co., Ltd. was established in 2006 and currently has fixed assets exceeding 500 million yuan. Its parent company, Dalian Sunshine Boiler Auxiliary Equipment Co., Ltd., was founded in 1998 and is located in the Yaojia Industrial Zone, Nanguanling Town, Ganjingzi District, Dalian City. It is one of the largest manufacturers of boiler auxiliary equipment in China.

One set of 15-ton reciprocating grate furnaces from Jiangsu has been shipped.

One set of 15-ton reciprocating grate furnaces from Jiangsu has been shipped. The reciprocating grate can be matched with boilers ranging from 1 to 160 tons per hour and is suitable for a wide range of fuels, including waste and biomass. The entire combustion surface of the grate consists of movable grate bars and fixed grate bars, which are arranged in an alternating, stepped configuration. Driven by a reducer (or hydraulic device), the movable grate bars perform reciprocating motion over the fixed grate bars.

Dalian Huiying Machinery Factory shipped one 6-ton chain-grate furnace to a customer in Jiangsu.

Dalian Huiying Machinery Co., Ltd. was established in 2006 and currently has fixed assets exceeding 500 million yuan. Its parent company, Dalian Yangguang Boiler Auxiliary Equipment Co., Ltd., was founded in 1998 and is located in the Yaojia Industrial Zone, Nanguanling Town, Ganjingzi District, Dalian City. It is one of the largest manufacturers of boiler auxiliary equipment in China.

MESSAGE